Readers Machines

Now live on the Boleyn Workshop

Visitors to the Boleyn Workshop Website have their own machines that they want to share with the world. I can reveal that the first pictures will be from Jamie Paul in Australia with his Coronet Major.The Boleyn Workshop is delighted to offer anyone with Coronet machinery the opportunity to post their pictures for the common good. Contact Pete via email dorsethammer@hotmail.co.uk to discuss number of pics, suitability etc. It is entirely free, confidential and unconditional. Don't be shy, if you've read this far you must be one of us! Even if you don't know it yet.

Please do not send nude photos or pictures of machines in provocative poses. Thank you. That includes people who have already sent these in, you know who you are.

The first to go up in the Readers Machines section is Mr Jamie Paul from Sunbury, Victoria with his Coronet Major and eclectic collection of attachments.He believes that his machine may be complete from the factory. From what he was told when he bought it, it was from RMIT which is a Tafe/University in Australia. He assumes it was used by them for many years and then sold to the person he bought it off. He claims to know that there is a university that still has one in a glass box that they aren't allowed to use, as it doesn't meet Australian standards. I for one would like to know where that is. It would certainly meet my standards.

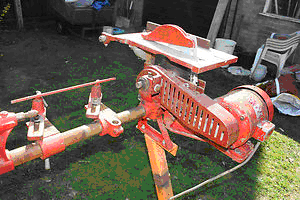

Before this Coronet Major is shown in its full restored glory, below is what it looked like when it was purchased by Jamie...

Below: A closer look at some of the attachments before restoration. Crikey mate, best open a tinny and get to work.

On second thoughts, make that several tinnies.

His Coronet Major bears the serial number 187 and is dated Nov 1976. And you can only wonder about its movements from Derbyshire, England across the oceans to the territories of Victoria,Australia. What portent might have precipitated its journey. I can't believe it damaged a county bridge in my home county of Dorset but admittedly they can be quite cumbersome even when mounted on decent castors.

This rare speed reduction gearbox unit has managed to keep an original white knob.

The finish on these hold down springs are indicative of the quality of the restoration.

The mortising jig before restoration showing some serious looking rust but fortunately still with its black handles.

Looks great now doesn't it.

And here it is, in position on the lathe bed with a mortice chisel staring at it right in the mush. Ready for work. Timber, start trembling now.

The Coronet Tool Co insignia on the belt guard is in prime condition after restoration. You can even make out Australia in the gold embossed map of the world, proving Coronets world domination. Actually it might not be Australia as I'm not too good at geography but the sentiment is there.

The planer/rebater in complete and impressive form with an interesting assembly of hold down springs. Is this factory fitted or home engineered? According to an old catalogue these are indeed factory made but with the wooden additions by Jamie.

The end turning rest and face plate after restoration. Look at that nut and bolt for attention to detail.

The combination table.

The combing joint fence with some kind of adaption.

The 10 inch circular saw table attached to the headstock and spindle before restoration. I bet it's going to look good when it's done up. The 3 point turning handle for the saw tables rise/fall mechanism is missing its balls (a bit like my Boston Terrier) but these can easily be replaced on the lathe. (Unlike my Boston Terrier) There's your first job sorted.

See? Told you. What a little beaut!

Here is the motor before restoration with the rare speed reduction gearbox on the right hand side.

Here is the finished article, less a few of the attachments obviously. Apart from the machine, look what a cracking job he's done on the cabinet.

Well done Jamie, a great start to Readers Machines.

If you have enjoyed looking at Jamies machine and restoration and would like to comment on them, then why not leave a message in the Guestbook? Just click on the highlighted text.

STOP PRESS

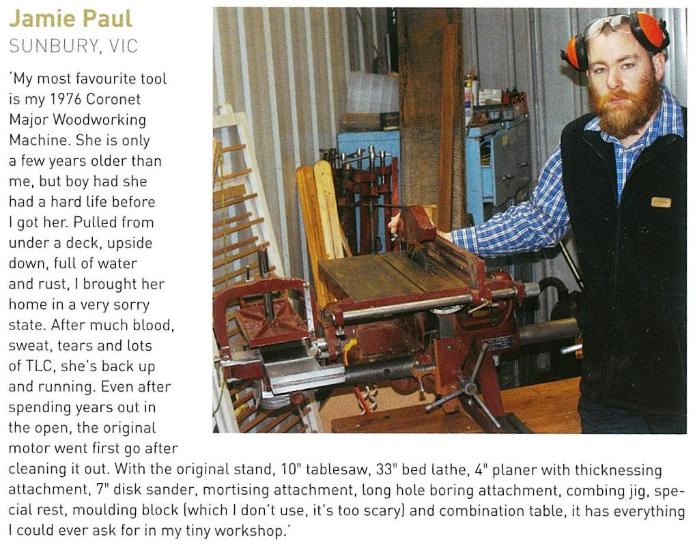

In August 2012 Jamies machine won a place in a competition in an Australian woodworking magazine to find their readers favourite tool or machine. There were over a 1000 entries.

Now we have pictures of a Coronet Minorette sent in by Simon. He used to have a Shopsmith but sold it and bought the Minorette off ebay with the proceeds. Now that is an attractive and compact woodworking centre.

He finds the Minorette more manageable and more precise. The saw stand he built himself using the machine. Good to see a unit getting some action. Thanks for the pics Simon.

Below is a view of the cabinet showing his adaptations for his machine.

Thanks again for sending your pics in Simon.

Now we have a Coronet Consort sent in by JJ. It has a date stamp of Aug 1976. In February 2011 I had a lengthy email from a Coronet Consort owner willing to share some photos and the story of how he came across it. But first a brief background. JJ trained as a mechanical engineer and enjoyed working with metal. Having a carpenter for a father meant he also picked up some woodworking skills and his first piece of woodworking machinery was a small table saw. He was able to now take on bigger products and complete them in a quicker time. But by the time the saw was two years old it was beginning to show its age. The guides were slightly out and setting the blade depth and angle were becoming more of a trial. By chance a relative sadly died and his father was asked to clear out his garage. In and amongst a huge amount of stuff were not only one or two handy things but this odd red thing. He didn't recognize it but hung on to it all the same. As he searched through the rest of the garage more and more of these bits of metal turned up all painted the same red colour. Upon his return home he showed the collection to JJ and asked him what he thought. All the bits were clean and free from rust and had obviously been well looked after. He set to work and slowly but surely it started to emerge that he was in the possession of a little gem. He could not believe what he was finding, a table saw with a planer thicknesser, a slot cutter with all of the cutters, a disc sander face plate, a belt sanding attachment and a face plate for wood turning. He researched the machine on the internet before finding the Boleyn Workshop and kindly deciding to share his story and some photos. (It's worth noting that a later (post 1976 blue colour) version of this machine sold for over £200 on an online auction site recently)

Here it is, like he says, a little gem. Nice stand too.

The combination table with the sanding disc.

Add on another pulley or two and hey presto, the belt sanding attachment. It's looking better by the minute.

By removing the extra pulleys and adding on the six inch face plate for woodturning the real versatility of these machines is being demonstrated.

The slot mortiser attachment and selection of chisels.

This shows the hold down springs for use with the moulding block. And what a cracking little box of cutters, quite a selection there.

The planer thicknesser attachment.

Thanks again JJ for taking the time to send some pictures in.

It's May 2011 and I get a request for a copy of the Coronet Minor manual from a man called Derek by email. By chance he only lives about ten miles away and is happy for an unknown person from the internet to arrive at his house. (I tell my kids not to do this) Fortunately it's me brandishing the manual copy and he lives to turn another day. He has recently bought a Coronet Minor off ebay and what a little beauty it is. It's a '67 according to the date stamp on the bed bar but is in great condition after a good clean up. He also purchased a mitre fence from me which I tested on my machine, a '76, before I left. However, imagine my surprise when it failed to fit in his saw table by a possible 1/16th of an inch. There must have been a slight change of design in the spec between 1967 and 1976. A practical man though, he can adapt it to suit and better still agrees to enter his machine in to Readers Machines. As soon as the photos arrive they will be posted here. And as I type they arrive in my inbox and oh no! they they are in a zipfile...I will have to get one of the small people to work on this. (Two days later...) It's a miracle! I have decoded the photos and enlarged them to fit the page thanks to the help of my daughter.

Above you can see the entire setup which has been bolted down to a sturdy homemade workbench. Derek has the basic lathe for turning with saw table, planer/thicknesser and the mortising attachments. Note the mitre fence in position and ready for work. In the ubiquitous box of bits underneath the worktop came faceplates and some damn sharp sawblades. Surprisingly though it came without a chuck or any centres for turning, something which Derek is busy remedying.

Above you can see the pleasing condition for the year of the overall paintwork. Note the two beltguards, accessories purchased by perhaps a more anxious original owner.

A close up of the saw table and belt guard with the top raised. I like to see a bit of sawdust on a bench. Proof of a working machine with a purpose in life.

The far end of the bed with the combination table and small tool rest on display. (Also in photo are the thicknesser and mortising attachments) Altogether a very tidy example of an earlier Coronet Minor and more importantly, one that is being put into use. Many thanks for the photos and better still the chance to inspect this little beauty myself. And there are some more photos to come. Altogether a great effort from a fellow enthusiast. More recently I recieved an email from Derek informing me of a Coronet Major purchase which I can not wait to inspect. And tap him up for some photos for the site too. Derek made the bench below solely with his Coronet Minor from some teak or mahogany door frames. And I have sat on it to test it.

Next up in Readers Machines is Mr Isaac Hock of Enfield, Middlesex.

(above) Before...

Who turned his Coronet Major in to a Boston Terrier.

(below) ...and after.

Well thanks for getting in touch Isaac Hock but this is not quite what I'm looking for here. Come on readers, pictures of your machines please. No commitment or liability whatsoever.

Send your pics to dorsethammer@hotmail.co.uk

Now this more like it!

I recently recieved an email via the Boleyn Workshop that just blew me away. A Mr Ashley Lister from Boston Lincs no less, contacted me asking if I'd be interested in seeing some photos of his machines. Having become somewhat cynical of late (it's a seasonal thing) I thought that there might just be a half decent pic or two of some rusty old machinery in an old shed somewhere, vaguely splotched with the now familiar red or maroon paintwork. Some rusty metal and some oily sawdust perhaps. But no. What I saw next changed my life forever. Click on the link below and revel in a bit of maroon and red. I can't copy the damn photos for this site at the moment (if only Coronet had made a computer everything would be so easy on it).

http://s183.photobucket.com/albums/x146/123ARL/1971%20Coronet%20Major%20images/

See below for a taster...

Now let me mash up Ashley’s words to describe these epic acquisitions. He purchased a 1971 model with a 7/8" spindle on *bay for £52 complete with virtually every attachment and extra ever made for the Major less the bandsaw. It looked very sad and neglected when collected but on closer inspection it was in remarkable good condition and cleaned up nicely. Not all the attachments are shown in the images in the link including the 14" sanding plate and tilting sanding table, wobble saw, moulding head/cutters and numerous small bits and pieces. He has now replaced the spindle with a 3/4" one - again purchased, brand new, on *bay for £10, solely so he could match it with a modern scroll chuck. He also acquired suitable 3/4" faceplates and screw chucks.

All the 7/8" face plates etc are now used on a 2nd 7/8 spindle 1974 Major purchased from *bay for £32 also with a good selection of attachments and sound mechanical condition. (You just have to love these things) Both lathes are now set up in The Shed, the 2nd machine permanently mounted with headstock at 90 degrees and bowl turning attachment fitted for bowl work. A bit of a turn-around and a cracking idea.

A 3rd very poorly and stark 1976 Major with just basic motor, bed, headstock, tool rest mountings, tailstock and mounting feet was purchased and has now been added to the fleet at £25. Unfortunately the machined locating groove on the bed bar was seriously damaged but he was able to cut the bed down so it just takes a toolrest mounting bracket with the belt sander from the 2nd lathe fitted permanently to it between the support leg frames - looks like a 10" bed lathe now. And what a great rescue too.

His most recent acquisition is a Coronet Imp freestanding 3 wheel bandsaw which was found on *bay. It came with a 4” belt sander which was described as an attachment for the bandsaw along with an extra drive pulley and an unusual and not seen before mounting bracket. Possibly a real rarity. A quirky yet functional adaptation to this machine are two toothbrush heads mounted in brackets to the rear casing that act as wheel brushes. I believe most modern machines are fitted with these, my first machine a Record did. This is some of what makes these old machines so interesting, you can but wonder about the person who made these and what his skills were.

These holders are no bodge jobs though, they are both well made and expertly fitted. A classic marriage of engineering and dentistry.

See below for the upper one...

And here's the lower one...

Unusual but would be a popular attachment if manufactured. Overall this Coronet Imp is in great condition.

Next up is an impressive Coronet Consort presently owned by an old mate Bernie from the West of England. He acquired this machine as part of a job lot from a man who used to make grandfather clocks. You can see why the Consort and certain attachments would be ideal for this.

Bernie sold me my first Coronet Major several years ago and we remained in touch as we share the same love of quality machinery. Not that we want to pick out curtains or anything. Now I don't think my pictures really do it justice but here goes.

From right to left, saddle and banjo, mortising attachment, belt sander and saw table. Note the long bed fitted to this Consort to allow woodturning, the short bed is in the foreground.

From right to left, planer/thicknesser, saw table, belt sander, morticer. Note that the planer looks virtually unused and in a mint condition.

The table saw in close up shows that is the same size as that of the Major give or take an inch or two as we measured it. The Consort saw table is made of aluminium and therefore a damn sight lighter!

Close up of the front of the saw table. The small rack and pinion assembly for adjusting the saw table height is indicative to the weight of the table!

The short bed bar. On the bench, the wobble saw inset for the table saw. My only gripe with the Consort is that like the Minor the bed bars do not have the rebated groove like the Majors.

There it is, the Coronet logo. The image of confidence and guarantee of top notch engineering. Overall this is a sterling set up and a working collection not a showpiece. Thanks Bernie, for the oppportunity to photograph your Consort and the hot dogs for lunch.

So what do Coronet Consorts and London buses have in common? Well they're both large and red, furthermore none come along for ages then several come along at once.

A Coronet Consort from South Africa

Ben sent me these which were put up by the *bay seller listing the machine.

Never mind the machine, what a nice bench. And how about that vintage pencil sharpener attached to the bench below? Nice touch.

Next up is Ernest's Coronet Minor...

I felt that Ernest's sterling effort for Readers Machines deserved it's own page so click on the link below for a full exhibition of his Coronet Minor (nearly) Ten in One machine.

Ernest's Coronet Minor

Please enjoy and sincere thanks Ernest.

A Coronet Minor restoration project from Chris. (Not my brother)

Chris sent in photos of Coronet Minor purchased off *bay with the intention of restoring it. He sent them in June and I have only just been able to post them due to technological difficulties ie me. Hopefully he is having more success and as he is dealing with well engineered steel and not troublesome technology it is highly likely.

Chris sent the original *bay pictures which is why they are small not the best quality. But you can still view a useful little lathe and saw table on a purpose built metal stand. Thanks for sending the pictures in Chris, and I look forward to viewing your progress.

I had an enquiry for a manual from Rupert in Cheshire who duly sent in a picture of the his recently acquired Coronet Major lathe. The drive belt had snapped and needed replacing henceforth the need for an instruction manual. There was also the ubiquitous box of bits that needed identifying. The piece he has mounted on the lathe is to be a mallet, in teak, for his wood carving hobby. The lathe used to belong to his wood-carving tutor’s father-in-law which is how he came by it. He updated me to say that the belt had now been replaced. Note the polyvee pulleys, nice touch that along with the colour coordinated apron hanging off the saw table. And although the paintwork is somewhat jaded you can be sure that the steel underneath is as good as the day it left its Sheffield forge. None of your new age monkey metal there. Hopefully we will see the contents of the box of bits in the future bolted to the frame and ready for work. Thanks again, Rupert.

A Coronet Minor sent in by Neil in Cambridgeshire.

Neil had been thinking of building a pole lathe for some time but had never found the time for it. So instead he started looking around the Cambridgeshire area for a lathe. The first couple he looked at were unsuitable but at last he found this decent little Minorette which was handily mounted on a purpose made bench. There are some other photos which I now have to find and post.

I seem to have mis-labelled these photos. Below is a Minorette sent in by Ian Epps of Fareham.

Please go to More Readers Machines

- FOR SALE

- About the Boleyn

- Home

- Zakwood Workshop Embu KENYA

- Julian Harrisons Workshop

- Inside the Boleyn (2005-2012)

- Inside the Boleyn 2013

- Inside the Boleyn 2014

- Inside the Boleyn 2015

- Inside the Boleyn 2016

- Inside the Boleyn 2017

- Inside the Boleyn 2018

- Inside the Boleyn 2019

- Inside the Boleyn 2020

- Inside the Boleyn 2021

- Inside the Boleyn 2022

- Inside the Boleyn 2023

- Inside the Boleyn 2024

- Inside the Boleyn 2025

- Technical Stuff

- Speed reduction gearbox fitting and operating instructions

- An Interview with Derek Pyatt

- Apollo no1 stove

- Coronet Imp bandsaw-blade-setting-advice

- Coronet Imp official hints on using

- Brook Gryphon 1hp motor connection diagram

- Charles Parker

- Coronet advertising etc

- Coronet Woodworking Machines catalogue

- Coronet Capitol planer

- Coronet Sovereign planer

- Coronet Classic 10 bandsaw

- Coronet Imp bandsaw

- Coronet Consort

- Coronet Elf

- Coronet Hobby lathe

- Coronet Home Cabinetmaker

- Coronet International Woodworker

- Coronet Major

- Coronet Majorette

- Coronet Major General

- Coronet Minor

- Coronet Minor paperwork

- Coronet Minorette

- Ernest's Coronet Minor

- Readers Machines

- More Readers Machines

- Even More Readers Machines

- Yet More Readers Machines

- MILFs

- Guestbook and comments

- Heimag A5 Tischbohrmachine