Inside the Boleyn 2015

January 2015

Due to personal reasons the Workshop was closed for the month.

February

After a difficult of period of time when family had to come first and interests second, I have been able to take tentative steps back to the Boleyn and weigh up where to start again. My kemo sabe AC has piped up with an interest in learning woodturning so what better machine to learn on than a Coronet Major. However before we can begin the first lesson the machine has to be put together. There are roughly 2 1/2 Majors stored unrestored (see what I did there?) in the Boleyn so I inspected the tidy ahem, stack of parts and pulled out a 48" bed bar with feet and headstock base and set it on the rolling workbench that the Majorette arrived on. Ah yes the Majorette. Wasn't I going to start that resto in 2012? Yes I do believe I was but I'm in charge here. At the moment I think I will set the Major for turning but leave on the extension bar so I can add the saw table and planer if required. That brings it up to date and hopefully we will be back to Monday night workshop and Tuesday night football soon.

On the technical front after much struggling, swearing and head slapping, I have reorganized the site home page and the Inside the Boleyn page. I felt that the home page should have pictures and text of the types of machine featured here rather than an ongoing diary of events. This is more suitable on the Inside the Boleyn page. Man that was hard work. It did my head in to be honest. There was probably a far easier way to do it but I did it my way. Hey that's catchy, would make a great song. Back soon...

February 21st

AC arrived bang on 11am this morning and after a quick brew we headed up to the Boleyn. The plan was to set up a Coronet Major for woodturning. This one was purchased in Witchampton but had spent most of its working life in Scotland before being brought down south by the owners daughter and son in law after bereavement to be sold. The previous owner had had an interesting life being involved with forestry development abroad in the 1950s.The bed bar was already on the bench with feet and headstock base already attached. Also on the bed were two saddles and the tailstock. A swift look over revealed some surface rust on the bed and some more serious rust and grime on the saddles particularly the plungers. The latter were going to need stripping and cleaning as they reused to remove on testing. To start we undid the allen bolt (a 1/32 if I remember correctly) holding the foot in place and slid it off. Then the bed bar got a right coating of Wilkos 3 in 1 so we could slide off the saddles when stripped. We eyed up the plunger warily. The knurled nuts, sounds painful, were seized solid so some force was required to loosen them but off they came and the retaining cap was removed revealing the spring and the spigot. All these parts were given the wire brush treatment and came up well. I keep saying this but the quality of the steel and parts for these Coronet machines means that they will virtually always come up ok. The bed bar was rubbed down with a 240 grit sandpaper and 3 in 1 oil before we slid the saddles back on and refitted the plungers. We made sure they moved freely before screwing on the caps and then banjos were fitted back on. Next we had to look around for a motor and NVR switch and also the motor plate to fit on. What we found was an elderly motor with the plate attached and separately an ancient Startet switch which came from the Majorette if I remember right. To be honest there was a bit of a struggle to fit the motor plate to the headstock as it was attached to the motor and I would recommend removing it even as a two man job. However eventually we managed it and bolted it up tight. The drive belt seemed to be adequate so it was left on. I was not amused to see that the pulley on the spindle did not align with the pulley on the motor and the belt is running across at an angle so that will need to be sorted out. But all in all a good productive session in which AC showed his worth. Just the rewiring and general bolt tightening to be done before it is a working Coronet Major and woodturning tuition lathe. Uh oh, rewiring...(shakes head and remembers WT700 bench drill).

23rd

Another Monday morning and once I am left alone in the house there was nothing to stop a rewiring session in the Boleyn. After my last failed attempt at rewiring which left the workshop and house in darkness I was not overly confident for success. I inspected the switch and the attached cables for the first time since it arrived five years ago and was left wondering how the previous owner had not died from an electrical shock related death. I'm not sure that he hadn't to be honest but it wasn't mentioned at the time of purchase. There was at least three inches of bare wire on both live and neutral wires between the terminals and the outside of the box. Although the last 1/2" before the terminal peculiarly did. The earth wire was also over-stripped and hanging loose. (My dad always replies that he's doing this when I ask him how he's been.) How these wires had never touched each other I do not know but it was from a working lathe. To start with I detached the old mains cable from the motor and copied down the wiring diagram for future (half an hours time) reference. The box needed a good clear out being full of sawdust. Next I inspected the innards of the Startet switch and apart from the bare wires of the input it seemed to be correctly wired. To an untrained chancer like myself this meant that technically I could carefully replicate the present wiring with new cable and hope for the best. I don't recommend this so get some appropriate advice if at all possible. You might well shake your heads in disgust but we don't all have the training or finance to be H+S correct. From start to finish including two cups of tea and general daydreaming it took two and half hours. And it started first time. When AC turns up tonight he will be shocked but at least not electrically. Just the belt guard to fit before the turning starts. There was even time to clear some work space for the refreshment station.

March 2015

I'm writing this at the end of the month having experienced the usual technical problems and a definite slight lack of interest. This isn't to say that nothing has been going on however. Once the Major was wired up and that it was established that AC wasn't going to be electrocuted (as I don't think his Mum would like it) he commenced his first lesson. I set up a 2' long piece of 2x2 pine between centres and showed him some basics of woodturning. Beads, coves and vees. As he used each tool I was sharpening the next one on the Tormek. Despite my shameless tool name dropping the session went well and we decided we would devote the next few sessions to woodturning. AC is now on his second candlestick and growing in confidence on the tools.

However next week we are going to have to have a split session in order to shift on a Minorette restoration in order to bring some money in again. The WT700 is just waiting for the replacement motor to be wired in before it goes up for sale.

Another development was the forming of a refreshment station at one end of the long workbench in the corner. The previous one by the stereo having proved unfit for purpose. I simply laid a few tiles in an orderly fashion including a splash back and rearranged the plugs in the double socket so that the lighting could also be improved above the turning bench.

There has only been one request for a manual this month which was duly sent off. People have clearly finished Spring cleaning sheds and garages and have restarted all the hobbies that they're going too but it's never too late to dust off your classic Coronet and get it to work.

March 27th

I had an interesting email today from another Pete who is coincidentally another West Ham fan. This meant I had to call the number he gave. Born in Forest Gate and now residing in Ilford he had a planer attachment that needed a new home. It seemed only right and proper that it should come to the Boleyn Workshop. I asked him the big question. What do you think of Big Sam? There was silence at the end of the line. I cannot repeat the conversation but we were both unusually tactful. A mutual agreement was also reached that it hadn't been the same since the terraces had gone and we affirmed that once you were West Ham it was for life. Eventually we discussed the logistics of getting the planer from Essex to North Dorset but sadly nothing came of it.

March 31st

Went to the Royal Hospital Chelsea and ate fish and chips with a bona fide Chelsea Pensioner. How did that happen? All to do with supplying Coronet spares to Zak Muchinas workshop in Embu Kenya.

April 2015

What can I say but that it's been a rough month looking after my Dad in his last weeks on this planet and have hardly been up to the Boleyn. He died in Blandford Hospital on April 29th and I was fortunate enough to have been with him when he died. Not many people get to do that with their fathers, lots of people have that wish but circumstances often prevent it. The funeral will be on Wednesday 13th May and there will be a few making their way up from the West Country where he grew up and we spent time as youngsters visiting my grandmother in her Southside flat in Weston-Super-Mare. Many more from Dorset from where we moved to in the early 60s. The Boleyn Workshop will be closed all day not only as a mark of respect but also because I won't be there. Obviously. RIP Dad.

May 2015

We were up in the Boleyn the Monday night before Dads funeral. I didn't have to be but I needed to be. I felt that I needed the routine and the familiar surroundings, sights and smells of my workshop. Something to take my mind off the bizarre human ritual that we know as the funeral. It did the trick. AC hit the kettle on and fired up the sound system while I dragged out the Minorette that joined the Boleyn Workshop from Bristol late last year for a modest signing on fee. Funnily enough it was the last outing with my Dad that wasn't hospital related. Even funnier was that it transpired that there was a West Ham fan in the sellers household. Unfortunately he wasn't there to discuss the claret and blue issues of the day but I chatted with his son to determine the history of the machine. Back in the Boleyn it was time for AC to flex his muscles and haul the machine up onto the bench for inspection. The motor was considered to be "burned out" by the sellers family as it had produced a burning smell when started up last. Although the bed bar was covered in rust there was no evidence of pitting and the saddle was complete. It came with a sanding disc that was wound up tight on the spindle and not much else. But a good solid all round example of the basic Minorette. Two hours later it was stripped into single components and raring to get into a paraffin bath. The deconstruction had gone well with only some singularly resistant locking rings causing any delay. Not having the correct C-spanners was definitely a handicap. In fact not having any C-spanners at all was a bit of one to be honest. I got them to move by tapping them gently with a light hammer and a small cold chisel placed in the recesses until they could be wound off by hand. To be continued...

May 15th

STOP PRESS Approval has been given for plans submitted by the Boleyn Workshop to demolish the Would Store and replace it with an Olympic Workshop. Recent developments have identified a need for a separate workshop to be constructed to house recent machine donations from a Boleyn Workshop well-wisher. The new Olympic Workshop will be a spacious 12'x8' with an apex roof and will be constructed to Boleyn Workshop spec. A full dust extraction unit will be fitted to provide a better working environment for woodturning, sawing and planing/thicknessing leaving the focus of the Boleyn Workshop to be machine and general restoration not forgetting our duty of blasting out dub and punk to educate the neighbourhood.

Also...I was in B+Q recently acquiring some basic supplies for the Boleyn Workshop. Now I have already commented once on the gentrification of this once tatty DIY giant but this visit provoked more. I went for a coffee in the gentrifed refreshment area. There was the usual mix of OAPs, builders, mothers with young children and care in the community failures. Nothing too shocking or untoward there you might say. But not only was I served by a bloody barrista (coffee maker to you and me) but they were advertising an All Day Brioche. Bwahahahaha. AN ALL DAY BRIOCHE! Yeah I'm sure that Quentin and Tarquin of Unicorn Construction are tapping on the door politely at 8am for their macchiato and all day brioche. Bwahahaha! Do me a favour...

June 4th

Blimey where did the last two weeks go? Me and AC were up the Boleyn on Monday night and after a quick look at the Minorette we shook our heads and turned our attention to the Major and some turning. By pure chance I had swiped a lump of wood from my brother in laws woodpile and reduced it down to a smallish turning blank. It looked piney. Very pale with pinkish reddy knots, it didn't look rough enough to be burnt. AC quickly knocked a decent little candle holder starting with a 2 1/2" screw chuck and centre before removing the latter. It turned surprisingly well and was brought up to a good finish with fine grit sandpaper. I found out much later that this was a piece of Wellingtonia tree or giant redwood/Sequoia. And even better I have been invited back to help myself. It's easy to work despite being open grained, finishes up well and the knots look impressive. And it makes an interesting change from the routine local woods that we are fortunate enough to be surrounded by. But next week we have to get back to work.

June 11th

Back to work eh? Yeah well that didn't exactly happen. More interestingly the Boleyn Workshop had a new customer visit on Friday. A local chap needed a Minorette manual as he was putting together a machine he had acquired on a kind of permanent loan. Rather than post the manual approximately 10 miles he came to collect and identify a number of parts in his "box of bits". We had an interesting and useful chat amidst the chaos and I loaned him a couple of woodturning books. The Boleyn is in a transition phase right now as the construction of the Olympic Workshop is nearing a start date. In other words it's in a right state. The Bristol Minorette is stripped and spread out on the bench but has been covered by everything from cardboard boxes of stuff from the now demolished Would Store to the evidence of an industrious ACs woodturning project on the Coronet Major. Also taking up floor space is a Consort on a small trolley, the Minorette that my mate Derek kindly put together on a constructed bench and a newly acquired belt sander on a metal frame. Not to mention my Coronet Imp and the WT900 bench drill. "So," asked my visitor "what exactly do you do in here? What projects have you got going on?" Now that was a good question and one that I couldn't exactly answer at the time. With hindsight I could have just said that everything he could see was a project which wouldn't have been untrue. We are going to stay in touch and by the next time he visits there should at least be some order in the chaos or at the most a brand new workshop adjacent to the Boleyn. So what happened at Monday nights workshop? Nothing did because I postponed it until Tuesday. Tuesday evening was a bit of a learning curve. Following last weeks success with the piece of Wellingtonia we decided to put another bit up on the Major. This piece had a large and attractive red knot in the centre in the shape of a figure of eight and AC planned to make it a feature. We started out with the 2 1/2" screw chuck and revolving centre as per last week but when it flew off and smacked AC in the middle of his visor we had to think again. I changed the screw in the chuck to a larger one and also two longer ones in the side. We knew this wood to be very dry and soft but when it went flying over my shoulder just because I tickled it with a roundnosed scraper it was time for drastic action. Yes, a six inch face plate. This time it remained secure and with that lesson having been learnt by both of us AC just had time for a final shaping before the session drew to a close. Next week the sanding and finishing. I have yet to collect some more of this Wellingtonia but I will as it is easy to turn and attractive when finished.

Stop Press. WHUFC have announced that Slaven Bilic will be the next West Ham manager and the one to take the club forward into the Olympic Stadium. Although he was only at the club for one year he was a popular player and a law graduate to boot. Whether or not this is the right business decision has yet to be seen but this is a football decision and a West Ham decision so the Boleyn Workshop is 100% in support. And Dicksie will be back at the Boleyn too! I'd like to see a modern day footballer say 'no' to him.

I have had several cheeky enquiries as to whether I am going to be manager of the Olympic Workshop. I can reveal that indeed yes, I shall be the new manager. My reasons for taking the job are this:

I have ten years experience of managing a Premier League workshop and think I am the right person to handle the transition to a new site (a distance of approx 2 feet) while retaining the old facilities. I respect the Boleyn Workshop traditions and have a desire to return to working wood 'the West Ham way.' And lastly, no one else wanted the job. AC will remain workshop apprentice and catering manager.

Also some joker has asked if there is going to be retractable workbenches in the Olympic Workshop. Any more cracks like that and someone will be retracting my size 11 cherry red Dr Marten from their backside.

End of June

Last week AC finished off his Wellingtonia candleholder. He had sighted up a large red knot into the centre which came up admirably when sanded and polished. He used a friction polish for the first time with good results on the dry wood. Once that was finished we eyed up the Bristol Minorette which had remained motionless on the bench since last week. It was barely visible underneath the mountain of tools and boxes which were waiting for the move to the new workshop. Shaking our heads we decided instead to make a list of equipment to be sold and and a plan of action for the forthcoming Saturday afternoon which was being devoted to the Workshop. We desperately need to shift some machinery from the squad and make some space and raise some funds towards construction expenses. A shortlist was drawn up which included the Coronet Consort bench saw, the twin motor dust extraction unit and both the Walker Turner bench drills. 700 series and 900 series. A new drilling machine has been acquired and will be unveiled at the opening of the new workshop. Also to go up for sale will be one of the Minorettes, unrestored but cleaned and serviced and ready for work.

Saturday came and we started to clean and photograph the machinery before taking an hour out to go and pick all the cherries from my Dads house. On our return we set up the dust extraction unit for cleaning and burnt a load of scrap wood that was lurking around the Boleyn like a fanzine seller on match days.

Monday night session. Once more we cast our eyes over the Bristol Minorette which was visible again after some crafty re-stacking on the weekend. And once more we turned away in lieu of a more lucrative deal, a Minorette that was just going to be reassembled for sale. Out of interest this is the machine that my old mate Derek took on a short loan and for which he fabricated a useful little bench on castors and fitted a cheeky NVR switch. Overall it is in good condition and besides we do not have the time to fully restore this or anything else before the new workshop arrives. However to ensure that it goes off to its new owner in running order we stripped, cleaned and oiled everything before reassembling. But not without issue. With the first turn of a screwdriver I removed the grubscrew from the RH foot and promptly lost it on the floor. Work was halted for over 20 minutes while we searched for it but without success. Eventually we had to give up and fortunately I have a spare one. The feet were replaced and the headstock retightened. The saddle was cleaned with any threads being de-clagged on the wire wheel. Next a combination table was cleaned up and fitted in the socket on the saddle. This was all removed to fit a mortising attachment which had been in two separate pieces for storage. They fitted together like old friends and with the sliding beds and stop bars oiled was bolted down on the saddle once the banjo had been removed. A mortice chuck received the wire wheel treatment before being threaded onto the spindle. The last job of the evening was to add a planer on the extension bar before realizing it was seized up. Luckily by light rust only. But that can wait for another day as can any other bits and pieces we decide to let go with it. This one will be a genuine auction to use *bay jargon starting at £0.99p and hopefully going a lot higher! At the moment only the Consort bench saw is on the auction site but in a couple of weeks the Minorette will be joining it.

Have a look at the gallery below for progress on the Olympic Workshop.

July 2015

With the arrival and construction of the Olympic Workshop imminent it became even more clear that we needed to shift some stock from the Boleyn to get organized. Restoration of the Bristol Minorette had to be put on ice or at least left on the worktop while we added to the for sale list. Also up were some surplus dust extractors and sundry items. To date the Coronet saw has sold and gone, the WT900 sold but not collected and one dust extractor sold and collected. The Minorette has not gone up for sale yet as we finish cleaning and maintaining and decide which attachments are to go with it. And there is some choice. For now we are thinking a fairly basic machine of saw table, planer and mortising attachment along with a combination table. Then perhaps a sanding disc and grinder plus sundries. The Coronet saw made a good return on the original investment while the dust extractor saw a small profit but the WT900 barely covered its initial price if not taking a minor loss.

So cracking on with the Minorette after last weeks efforts we decided to strip and clean the planing attachment after seeing that the rust was worse than we thought. Also I thought I would take the opportunity to take a photo of the planer de-constructed with all of its components cleaned and on display. If Coronet did revenge porn it would look like this...See below.

We started by removing the pulley wheel which has a grubscrew for tightening on the spindle and also an allen bolt plus washer which taps into the end of the spindle and is reached inside the pulley wheel. At the other end of the spindle there is just the one allen bolt. Next we removed the spindle plates on either side and gently tapped them off the spindle so as not to dislodge the bearings. To enable us to remove the planer shaft we had to lower the planer table to its full extent and once it was out the blades were then taken out by undoing the six retaining allen bolts and the four adjuster screws while marvelling at the quality of the engineering. It might be an everyday sight to your average engineer but for myself it is always a treat to view this British engineering at its finest. At this point I had to leave the workshop to run an errand and AC took over the de-rusting and cleaning. On my return I found the planer shaft and sundry parts transformed and shining under the Boleyn floodlights, the woodturning shavings hoovered and the floor swept. My apprentice is worth his weight in biscuits.

All day Brioche update: when I returned to b+q to purchase and order the Olympic Workshop I needed a strong caffeine injection after that particular rigmarole. Just exactly how hard it is to pay cash for anything these days? But going back to the café I noticed that there was an all day brioche on display in the cake cabinet. I felt it my duty to inspect this offering having previously brought it to Boleyn Workshop readers (hi mum) attention. And it is nothing more than a posh bacon roll. No, I didn't buy it or eat it. Having experienced an all day breakfast roll from a layby canteen in my building days there was no comparison. We're talking a roll the size of a small loaf of bread filled with egg, bacon, sausage, tomatoes, mushrooms and even baked beans all defying gravity as you put it towards your mouth. And then there's the all day brioche. Bwahahha. Admittedly about 25% of the breakfast roll used to end up down my shirt and van steering wheel but I saw it as an investment for later.

After last weeks progress this weeks was disappointing. I had been somewhat fed up since finding out earlier in the day that the workshop I had paid for and ordered was actually out of stock and wouldn't be arriving for another two weeks at least. Knowing that all day brioches were available in their Poole store was of no comfort whatsoever. I was struggling with the simple task of rebuilding the planer despite it all being set out and AC wasn't in the mood for de-clagging on the wire wheel. Trying to concentrate enough to work while on painkillers was proving impossible this evening. I couldn't get in to it and on the stereo even Desmond Dekker couldn't get it if he really wanted. Eventually we decided to give up all pretence of restoration and decided to take up a project of making a working dust extractor out of an old model with no hose and a decommissioned Vax machine. Between them both there was one good machine waiting to be discovered. The extractor had a broken hose socket and no hose and the Vax wouldn't suck but had a decent hose. We cut a large section off the front of the Vax that included the hose socket and removed the broken socket from the extractor bin. When pressed against the front of the extractor the cut piece only needed slight pressure for the difference in profile to be ironed out. We marked out and drilled eight bolt holes in the new socket piece and raided the house larder for a cornflakes packet to make a cardboard gasket from. Next we placed the new piece against the bin and transposed the markings for the drill holes before drilling them through. It transpired that the wheeled base of the Vax would slip exactly into the base of the bin making it able to be dragged around the floor by its hose. We ran out of time to finish the project but its first up in the workshop next week when photographic evidence will be submitted.

Finally I have a delivery date of July 25th for the Olympic Workshop and hopefully the erection team (no, not Spurs first XI) won't be far behind to do their job. As I am recovering from my bi-annual epidurals I have taken some time to reorganize the site. The Inside the Boleyn page has been broken down into separate years to save the endless scrolling down both to read and update. I realize that doing all those cones for the jewellery display scarred me for life. I cannot bear even scrolling down past them to update the page but now I can just open up the 2015 page in safety.

August 2015

So the Olympic Workshop arrived in late July and sat on the driveway for approx one week before being erected but not by the erection service I had paid £120 for. It happened like this. On the morning it was due to go up the contractors turned up as planned and went into the garden to make a start. Imagine my surprise when an hour later there was a knock at that door and one of them, the one that looked like Jonah Hill from the film Superbad, announced that 'we' apparently had a problem. We went up the garden expecting to see a large erection in the garden but the only erection I could see was his mate who looked like the funny one from the tv show The Office (not Ricky Gervais). The only problem I could see was that they hadn't built the bloody shed. Then came the bombshell that apparently their firm insisted on a clear four foot working area around the whole base and they weren't allowed to use the clients ladders only their own approved stepladder. Yet somehow they had managed to lay the chipboard floor and lean the back end panel up against my neighbours wall before noticing that they were 'unable' to do the job. And furthermore Jonah Hill had already spoken to his area manager who had told him not to do it. Now I've put up a few sheds in my time, I've built site huts, cement sheds, karzis, to name but a few. And when I chose the site for the new workshop I made sure it was in a do-able position. Ok, so you would have to spend ten minutes in my neighbours garden on a ladder to fit the rear fascia and reach the back to tack on the felt but that was it. And my neighbour that side is as good as gold. Is there no way to resolve this, I asked. Perhaps a goodwill drink be involved for the extra effort? But even as I asked this I noticed that the Office guy was already packing the tools away. Jonah Hill then proved his comedic worth by offering to come down on the Saturday instead if I phoned his office and told them I was going on holiday and needed the job done. How that made the site suddenly fall within their parameters I do not know but I saw what he was after. Saturday morning job and double bubble. And no doubt while noshing on down an all day brioche. Do me a favour. Jonah and his mate were sent packing and I got on the phone to demand a refund on the erection service though to be fair I did get two erections turning up to do the job. I got the refund. I blame the gentrification of b+q which is obviously leaking down to its contractors, too precious to work outside their parameters, no motivation or initiative to get the job done, and clearly no pride in being a contractor.

Workshop sales are going well and the space is being welcomed. We had prepared a Minorette for sale in the last couple of sessions by stripping and cleaning all the moving parts and making sure they were well lubricated for use. It was a basic unit of saw table, mortiser and planer and added to this were a grinding wheel and arbor, mortise chuck plus one chisel and combination table. And a free manual of course. I have become disillusioned with *bay and its extortionate fees so decided to try a different tack and put it on www.gumtree.com. The advert had only been live for about three hours when it was snapped up by a local buyer for the asking price and on the following Saturday it was duly collected. The buyer, Mark, was absolutely delighted with the machine and very enthusiastic with the Coronet brand. We spent about half an hour in the workshop going through the machine setup and over the functions of the attachments. Mark was really impressed by the quality of the engineering and the sheer inventiveness of the design. All in all a good transaction.

Blimey it's near the end of August already. The WT900 has been collected by a nice fella from Cornwall who runs his own engineering business. Although he has a factory with all the kit he wanted something decent at home to do his drilling jobs on. I was sorry to see it go but I still have the 900s little brother, the WT700 and also this beast of a Meddings floor standing drill was donated to me by my wifes godmother along with the contents of her husbands joinery shop.

AC has been away on holiday but in an earlier evening session in the Boleyn we actually saw the workshop floor for the first time in what seems like ages. It might actually be his first time. We decided to keep the remaining Major for a winter restoration project now that we have plenty of room to work around it. There are still approximately two Minorettes on the workbench and various boxes which will be finished up first. The Olympic Workshop is currently full of joinery stuff which needs sorting. A feature on the Olympic Workshop coming soon.

John Hendrie sent in some interesting photos of his machine for identification. You can see them here in More Readers Machines just follow the link and scroll down.

September 2015

A quiet month and not just because AC had skived off on holiday and to a couple of festivals. We had a friend from Nepal staying with us for a few weeks and were busy arranging support for his plans of building an orphanage in Kathmandu on his return along with my Nepali penfriend of fifteen years who had introduced us. There was lots to discuss and we shall be starting up the UK base of the charity from our home while they run things on the Nepal side. Much entertaining was done too with family and friends being introduced to traditional Nepali cooking by Sunil who until recently ran his own restaurant. There will be a link from this website to the charitys once it is set up.

Last week was our first turning session in a while and more than that our first on another brand than Coronet. Amongst the machinery I was kindly gifted by my wifes godmother is a compact and solid little beast in a light green and cream colour scheme. It's not without some guilt that I announce that it is a Myford ml8. (blushes) However I am going to be objective about it. Now the godmothers partner was a very skilful man having been not just a carpenter and joiner but a pattern maker for aircraft too. Coincidentally he worked at De Havillands in Hatfield, Herts the same as my own grandfather but in later times. And I'm guessing that this aircraft factory was where he (the partner) acquired another stalwart of the English engineering works, the Meddings pillar drill. But more of that later. Back to the ml8 and what first interested me to this machine was the small footprint compared to that of the Major (Heresy! I hear thee cry! String him up by the knurled nuts!) The electric motor is slung under the headstock which not only reduces the amount of space taken up in the shop but also gives it a low centre of gravity which makes it more stable. Then there is the ease of belt change using gravity to maintain belt tension. (Sorry Mr.Parker boss, it just is better.) In a packed Olympic Workshop and believe me, it is packed, space is at a premium. The ml8 takes up a small space, measurements to follow and even with a box of attachments underneath fits neatly against the wall. I knocked out 24 cupboard door knobs from a bit of 2x2 @30" in an hour or so and found the 4 speeds to be versatile and the lathe overall to be stout and well engineered. Back to Monday night and I have set up a lump of yew on the outboard spindle for AC to have his first crack at a bowl. The outboard turning attachment is excellent. Oh no what is happening to me? I'm loving this machine and for over fifteen years I have been "in a relationship" with everything maroon and/or Post Office Red. I'm going to have to go on a break and think about where my feelings actually are right now. And fortunately I am. On the 17th I am visiting Nepal for three weeks to meet my penfriend Badri for the first time in Kathmandu then travel to Chitwan along with Sunil where we will stay in the village where they grew up together. Rather than doing the tourist thing we will be meeting family and friends including the staff of Clinic Nepal and having meetings regarding the future of the orphanage project. I have some wood carving tools to donate to a local woodcarver whose work is being bought and resold to help raise funds and I hope to be returning with some for sale on this end. To get some content for my site I hope to be visiting local carpenters to show some tools and working techniques used in this area. What are the odds of finding an ancient Minorette tucked away in a backstreet? (None at all, Pete Site Admin)

AC will be attending the workshop on his own during my absence being a trusted key holder but there will be no website updates until mid to late October. Two orders for workshop manuals came in late this week, one digital and one paper, the digital of which went off to Victoria, Australia to a cobber who inherited a Coronet Major from his late father.

So until mid to late October...keep it maroon and red.

November

Wow where did the last month go? One thing of note is that I had a wonderful or grovelling email depending on your point of view from a Hugh in Cheshire who described the Boleyn Workshop website as "pure gold" in his blog. So here's the link he sent me.

http://www.ace-dog.co.uk/Workshop/Coronet%20Major/index.htm

There were only two workshop sessions up the Boleyn this month due to injuries. Mine was the more ironic of the two it's fair to say. After having travelled through Nepal as a helmet-less motorcycle pillion passenger, by overcrowded car, public bus, tourist bus and even a pregnant elephant without so much as a minor scratch it is definitely ironic that I should return home and slip over in the chicken run. How did manage that? In my defence it had been raining and I was definitely a bit woozy from the antibiotics I was taking for the infected mosquito bites that I did return from my travels with (they didn't count as a minor scratch) and that ramp was slippery. In the event I went down like a two bob tart. I managed to give myself reverse whiplash (?) and a decent little lump on the back of my head not to mention a bruised wrist. So that was me out of action for two weeks. Not to be outdone and clearly feeling in need of some attention AC broke his collarbone playing tag rugby. Yes the safe one. It's not easy but he managed it and is duly strapped up for several weeks. However he made it up for Monday night tea drinking and supervised me cutting the pieces for his younger brothers toolbox.

There has been a lot of email activity this month. The usual requests for manuals and general Coronet related enquiries. Kelvin of the Coronet Home Cabinetmaker fame has advised me that he wishes to sell his machine. I have agreed to host an advert in the hope that a true enthusiast will purchase the machine and enjoy using it whilst preserving for future generations. He is asking for offers over £175 and I think it is worth it. It is the only example of this unique model that most people have seen and has been sympathetically and competently restored. If you are seriously interested then contact me at pete@boleynworkshop.com and I will forward your enquiry on to him.

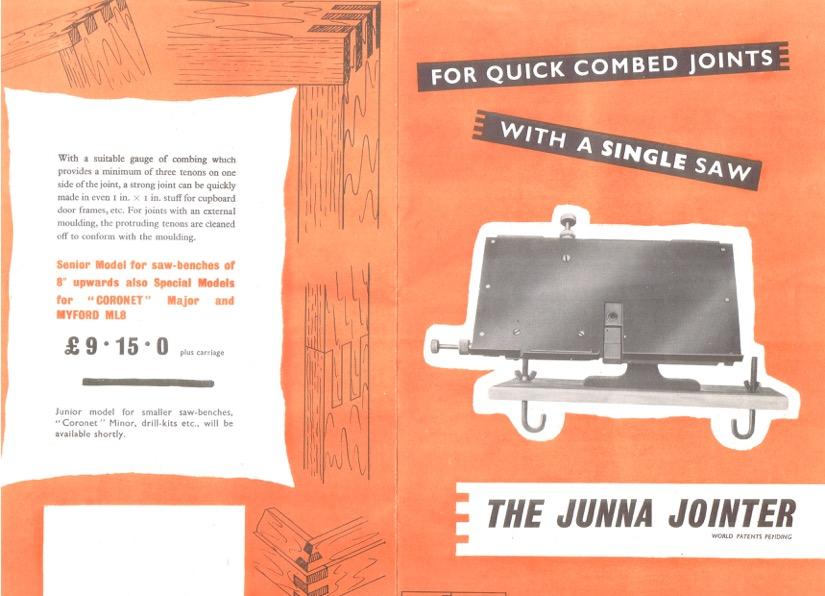

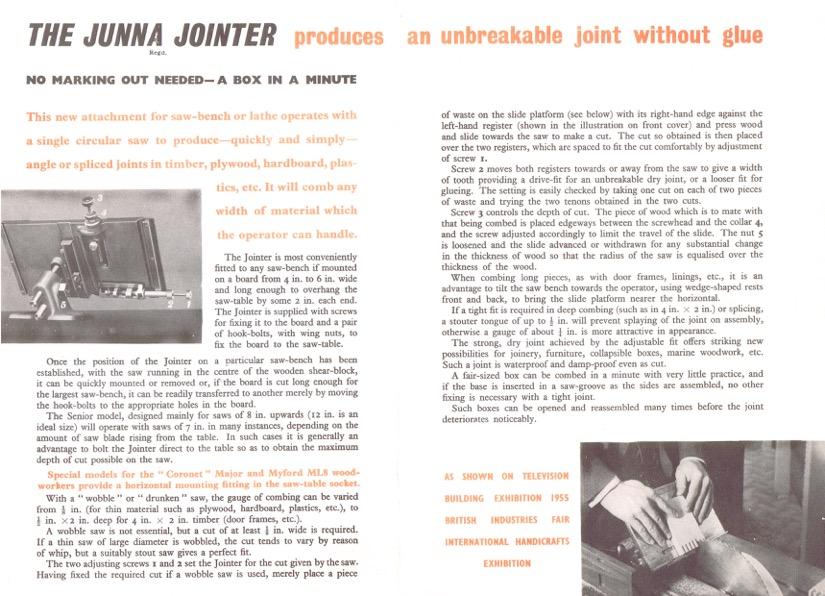

I have also struck up a correspondence with Chris from Newcastle under Lyme who is in possession of his late fathers Coronet Major. Interestingly Chris remembers going to the Derby factory to collect the machine with his father in 1956 and also how much it cost back then. £98 16 shillings and 6 pence! In my medicated state I got hideously confused between Chris and several other enquirees in my return from Nepal. He must have thought he had made contact with a complete fool (cough) and I still can't work out why it went so wrong out of all the enquiries. But to his great credit we are still communicating. He has a selection of original factory leaflets and attachments one of them being the "Junna Jointer" which he kindly scanned and sent to me to be reproduced below. Thanks Chris.

December

A busy week in workshop enquiries. Some Coronet Home Cabinetmaker spare parts have gone off to Dennis in Cornwall who is restoring one after seeing Kelvins feature on this website. I liberated a box of red machine parts from *ebay some two years ago now saving them from the scrapyard for sure. They remained in a box under the workbench awaiting restoration without me really knowing what they were. It wasn't until Kelvin forwarded me the pictures of his impressive restoration that I was able to identify them as CHC parts. The conical outboard turning tool rest was interestingly fixed independently to the worktop rather than to the lathe itself. What I had saved was one of these conical stands, two complete saddles with banjos and the long and short turning rest plus a selection of bits that may or not be part of this model. There is definitely a bed bar extension. I have promised to hold on to them until Dennis has finished in case they turn out to be a vital missing part.

I had a very interesting email from Paul Whittle who has been looking into the refurbishment of his Coronet Imps thrust bearings. On inspection of his Imp he noticed that the lower thrust bearing had clearly seized at some point as the back of the blade had worn a groove into the front of it. He is looking into turning some 'end caps' to fit over and then case hardening them before seeing how they work. It will be interesting to see the outcome as I get quite a few enquiries for replacement bearings. Also the industrious Paul has created an Imp saw table insert by means of a 3D printer no less! This is exciting stuff of science fiction and has dragged the Boleyn Workshop kicking and screaming into the 21st century, or at least the early 20th. See below...

There has been a flurry of manual requests (ok, it was two) from Scotland where some sort of maroon tartan revival must be occurring. Perhaps the oncoming Winter, if last years ever ended, is driving people to pick up an interest that will help them to endure until next Spring. And what better way than to stand in front of a piece of maroon machinery marvelling at the quality of the engineering. One of these manuals went off to Stranraer of Saturday afternoon final score fame. Scottish League Division 1, Cowdenbeath 2 Stranraer 0. Those words bring back the smell of coal fire smoke that filled the front room as we sat glued to the announcers voice in a way we never did at school, fingers still smarting as they thawed out, breathless from the last minute dash up from the rec after dragging every last bit of daylight out for goalmouth scrambles.

Back in the Boleyn and much the same as last week AC gulped tea and munched biscuits while I finished the cutting list for his brothers toolbox before gluing and cramping it together. Only three more Monday night workshops before Crimbo so it's probably time for a game of football.

- FOR SALE

- About the Boleyn

- Home

- Zakwood Workshop Embu KENYA

- Julian Harrisons Workshop

- Inside the Boleyn (2005-2012)

- Inside the Boleyn 2013

- Inside the Boleyn 2014

- Inside the Boleyn 2015

- Inside the Boleyn 2016

- Inside the Boleyn 2017

- Inside the Boleyn 2018

- Inside the Boleyn 2019

- Inside the Boleyn 2020

- Inside the Boleyn 2021

- Inside the Boleyn 2022

- Inside the Boleyn 2023

- Inside the Boleyn 2024

- Inside the Boleyn 2025

- Technical Stuff

- Speed reduction gearbox fitting and operating instructions

- An Interview with Derek Pyatt

- Apollo no1 stove

- Coronet Imp bandsaw-blade-setting-advice

- Coronet Imp official hints on using

- Brook Gryphon 1hp motor connection diagram

- Charles Parker

- Coronet advertising etc

- Coronet Woodworking Machines catalogue

- Coronet Capitol planer

- Coronet Sovereign planer

- Coronet Classic 10 bandsaw

- Coronet Imp bandsaw

- Coronet Consort

- Coronet Elf

- Coronet Hobby lathe

- Coronet Home Cabinetmaker

- Coronet International Woodworker

- Coronet Major

- Coronet Majorette

- Coronet Major General

- Coronet Minor

- Coronet Minor paperwork

- Coronet Minorette

- Ernest's Coronet Minor

- Readers Machines

- More Readers Machines

- Even More Readers Machines

- Yet More Readers Machines

- MILFs

- Guestbook and comments

- Heimag A5 Tischbohrmachine