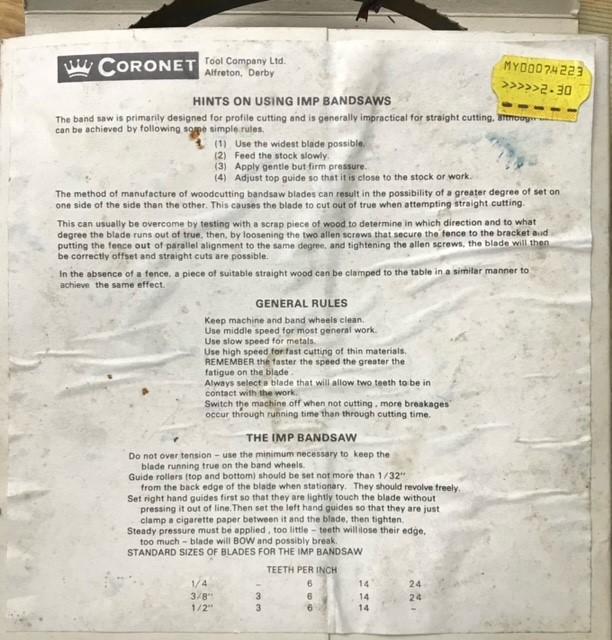

Coronet Tool Company Ltd, Alfreton, Derby

HINTS ON USING IMP BANDSAWS

The bandsaw is primarily designed for profile cutting and is generally impractical for straight cutting although this can be achieved by following some simple rules.

(1) Use the widest blade possible

(2) Feed the stock slowly

(3) Apply gentle but firm pressure

(4) Adjust top guide so that it is close to the stock of work

The method of manufacture of woodcutting bandsaw blades can result in the possibility of a greater degree of set on one side than the other. This causes the blade to cut out of true when attempting straight cutting.

This can usually be overcome by testing with a scrap piece of wood to determine in which direction and to what degree the blade runs out of true, then by loosening the two allen screws that secure the fence to the bracket and putting the fence out of parallel to the same degree and tightening the allen screws, the blade will then be correctly offset and straight cuts are possible.

In the absence of a fence a piece of suitable straight wood can be clamped to the table in a similar manner to achieve the same effect.

GENERAL RULES

Keep machine and bandsaw wheels clean

Use middle speed for most general work

Use slow speed for metals

Use high speed for fast cutting of thin materials

REMEMBER the faster the speed the greater the fatigue on the blade

Always select a blade that will allow two teeth to be in contact with the work

Switch the machine off when not running. More breakages occur through running time than through cutting time

THE IMP BANDSAW

Do not over tension – use the minimum necessary to keep the blade running true on the band wheels.

Guide rollers (top and bottom) should be set no more than ⅟32″ from the back edge of the blade when stationary, they should revolve freely.

Set right hand guides first so that they lightly touch the blade without pressing it out of line. Then set the left hand guide so that they just clamp a cigarette paper between it and the blade then tighten.

Steady pressure must be applied, too little – teeth will lose their edge, too much – blade will BOW and possibly break.

STANDARD SIZES OF BLADES FOR THE IMP BANDSAW (BLADE LENGTH IS 67½”)

TEETH PER INCH

¼″ - 6 14 24

⅜″ 3 6 14 24

½″ 3 6 14 -

Please note: this information is copied from an original Coronet Tool Company information sheet and supplied for general interest only.

- FOR SALE

- About the Boleyn

- Home

- Zakwood Workshop Embu KENYA

- Julian Harrisons Workshop

- Inside the Boleyn (2005-2012)

- Inside the Boleyn 2013

- Inside the Boleyn 2014

- Inside the Boleyn 2015

- Inside the Boleyn 2016

- Inside the Boleyn 2017

- Inside the Boleyn 2018

- Inside the Boleyn 2019

- Inside the Boleyn 2020

- Inside the Boleyn 2021

- Inside the Boleyn 2022

- Inside the Boleyn 2023

- Inside the Boleyn 2024

- Inside the Boleyn 2025

- Technical Stuff

- Speed reduction gearbox fitting and operating instructions

- An Interview with Derek Pyatt

- Apollo no1 stove

- Coronet Imp bandsaw-blade-setting-advice

- Coronet Imp official hints on using

- Brook Gryphon 1hp motor connection diagram

- Charles Parker

- Coronet advertising etc

- Coronet Woodworking Machines catalogue

- Coronet Capitol planer

- Coronet Sovereign planer

- Coronet Classic 10 bandsaw

- Coronet Imp bandsaw

- Coronet Consort

- Coronet Elf

- Coronet Hobby lathe

- Coronet Home Cabinetmaker

- Coronet International Woodworker

- Coronet Major

- Coronet Majorette

- Coronet Major General

- Coronet Minor

- Coronet Minor paperwork

- Coronet Minorette

- Ernest's Coronet Minor

- Readers Machines

- More Readers Machines

- Even More Readers Machines

- Yet More Readers Machines

- MILFs

- Guestbook and comments

- Heimag A5 Tischbohrmachine