The Coronet Home Cabinetmaker lathe circa 1950s

This little gem was brought to my attention by Kelvin Pitt who lives in a village near the Brecon Becons National Park. I have given it its own page rather than slotting it away in Readers Machines as it is such a unique machine. The story is thus: After a serious health scare in 2013 Kelvin did the sensible thing and bought a large workshop to take up woodworking. Let's face it, it was the right thing to do. And this, he says, was when the urge to buy an old wood turning machine came to play. He could relate to older machines being 63yo and having been a mechanical engineer for most of his life. But on no account did he ever think that he would acquire an older and indeed rarer model of this type of wood lathe. He doesn't know what drew him to this lathe, perhaps the lines or perhaps a primeval urge held since the time of swamp and cave dwellers to have a nice bit of kit in the shed. Have a look at the gallery and I have reproduced Kelvins own notes below in my own inimitable style.

PICS OF LATHE WHEN BOUGHT, (pics 1, 2 & 3)

This Coronet was purchased on 12th August this year (20150, through a selling site from a gentleman in Shrewsbury, not far from Kidderminster. Kelvin noticed the casting around the left hand ball race bearing had been damaged/broken off but whoever had re-welded it back together clearly knew his skill. The alignment across from small bearing block to large phosphor bronze sleeve bearing block was perfect. The rest of this lathe looked OK but to a mechanical engineers eye some TLC was required so it was stripped down to the bare bones like a squad of Harry Redknapps footballers.

PICS OF STRIPPED DOWN LATHE, (pics 4, 5 , 6 & 7) The main tapered phosphor bronze sleeve was in good shape although with a little wear but importantly but no flat spots or

run-out.

However the left-hand small ball bearing had been “fried” because it had been left in the casting obviously when it had been

welded. This ball race bearing is an EE55 or KLNJ5/8, R10 open, which Kelvin bought from a seller on *bay. Each component was inspected for cracks, splits and wear. Next two coats of red oxide were applied in reddiness (sorry) for

two coats of industrial Post Office red paint. This being its original colour.

PICS OF PAINTED LATHE, ( pics 8, 9,10 & 11)

The drive belt had obviously seen better days what with being approx sixty years old. Kelvin contacted Derek from Pyatt Woodworking and obtained a new belt and flip over oiler for the bronze bushing. The belt

(a “Z” profile) is 23 inches around the two opposing outer rim sized pulleys. (code on belt,Z22)

The Whitworth threads will require re-dressing as some threads have been 'flattened out' but in Kelvins words "overall she is

very good shape for an old lady." Cue mother-in-law joke.

The rip saw table and fence are present but it is in need of a blade. The cast iron pillar is for outboard bowl turning and

fortunately this came with this lathe. More than too often these are thrown out as many people don't realise they are part

of this machine. They are not an added 'bolt on' feature. Also present is the left hand tapered screw for mops, centres

and face plate.

See below gallery for text re pics 12, 13 &14

PICS OF RIP TABLE ETC; (pics 12, 13 &14)

The drive motor on this lathe is a original and genuine “Cub” and Kelvins emails to Brook Crompton UK LTD subsequently

advised him that this motor is a 1950's motor and would have been phased out in the early 1960's as the Gryphon motor

took its place. It is a lovely quiet motor and now runs even smoother as the grease pots have been filled with good running

grease.The original wiring to this motor was well past its sell by date having red, black and solid green coloured wires

and cracked black rubber outer sleeving. Kelvin rewired this cable with a modern equivalent wire

but still with the solid red, black and green coloured inner

sleeving. Still looks the part but safer all round for everyone. PICS OF MOTOR AND PLATE, (15 & 16) There were no belt or saw blade guards fitted on this lathe when it was built in the 1950's. The introduction of machine

guards came in at a later date and were more or less instantly removed so that woodworkers could

actually see what they were doing. (Added by Pete Site Admin)

PICS OF FINISHED LATHE PUT TOGETHER, (pics 17,18, 19 & 20) UPDATE....... Kelvin has found that on running the unit that there is a slight run-out on the drive shaft. This may have been caused through

it being

dropped causing damage to the ball race casting or overheating/warping to the drive shaft whilst being welded.

But the run-out of the

shaft is only 5-6 thou out, resulting on a throw-out of nearly a 1/16 of an inch on a 6 inch faceplate. He say that turning between centres seems to be ok.

Pete says: Many thanks for sending in the pics and text of this unique machine, probably the earliest Coronet machine

featured on the

site so far. Funnily enough Kelvins pics enabled me to identify several old Coronet parts that have been lurking in a box

under the workbench in the Boleyn for some time. If you have a similar aged machine then please

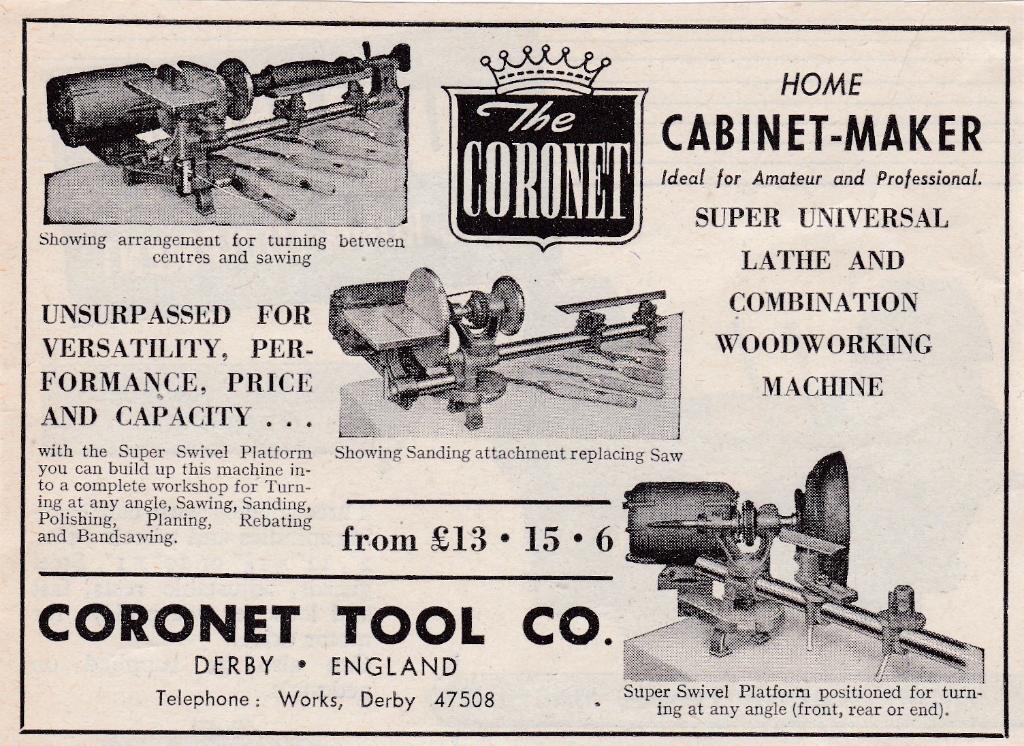

send in some pics. And what is wrong with the spacing on this page I do not know. Enjoy the advert below.

- FOR SALE

- About the Boleyn

- Home

- Zakwood Workshop Embu KENYA

- Julian Harrisons Workshop

- Inside the Boleyn (2005-2012)

- Inside the Boleyn 2013

- Inside the Boleyn 2014

- Inside the Boleyn 2015

- Inside the Boleyn 2016

- Inside the Boleyn 2017

- Inside the Boleyn 2018

- Inside the Boleyn 2019

- Inside the Boleyn 2020

- Inside the Boleyn 2021

- Inside the Boleyn 2022

- Inside the Boleyn 2023

- Inside the Boleyn 2024

- Inside the Boleyn 2025

- Technical Stuff

- Speed reduction gearbox fitting and operating instructions

- An Interview with Derek Pyatt

- Apollo no1 stove

- Coronet Imp bandsaw-blade-setting-advice

- Coronet Imp official hints on using

- Brook Gryphon 1hp motor connection diagram

- Charles Parker

- Coronet advertising etc

- Coronet Woodworking Machines catalogue

- Coronet Capitol planer

- Coronet Sovereign planer

- Coronet Classic 10 bandsaw

- Coronet Imp bandsaw

- Coronet Consort

- Coronet Elf

- Coronet Hobby lathe

- Coronet Home Cabinetmaker

- Coronet International Woodworker

- Coronet Major

- Coronet Majorette

- Coronet Major General

- Coronet Minor

- Coronet Minor paperwork

- Coronet Minorette

- Ernest's Coronet Minor

- Readers Machines

- More Readers Machines

- Even More Readers Machines

- Yet More Readers Machines

- MILFs

- Guestbook and comments

- Heimag A5 Tischbohrmachine