Coronet International Woodworker

I was contacted by a lady who wished to sell this machine on behalf of an elderly neighbour. It had belonged to her late husband who was clearly a man of good taste at least where woodworking machinery was concerned.

And finally another International machine appears...

At the end of 2019 I was contacted by Paul from High Wycombe who is the proud owner of only the third Coronet International I have come across so far. Paul has sent me approx two dozen great quality photos with annotated text which you can view in the galleries below. But first a detailed history of the machine and some general information in Paul's own words.

"Bought new from Derby by Eric Wright of Scarning in Norfolk in the early 1970`s

Eric was my Father in Law. Before the war he was at Loughborough College training as a handicraft teacher under the tutorship of Edward Barnsley.

At the outset of WW2 he joined RAF ground crew in Norfolk to repair and patch up American B25 Mitchell bombers. After the war he didn't go back to his teacher training but joined the family firm of J J Wright in Dereham and sold loads of Ford and Fordson tractors to Norfolk Farmers. In his spare time Eric made some really good well designed cabinet work in oak and walnut and also a revolving cedar wood summer house, with the framework mortice and tenoned on the Coronet International.

I inherited the machine on his death in 1991 and moved it down to High Wycombe and have used it ever since for my oak sign making business.

The International is built around a square cabinet containing the Brookes motor. It has a variable speed drive for the main shaft. This is the one thing that occasionally fails, the fixed pulley is held by 2 grub screws and with the side pressure of the sliding pulley via the v belt these have to be re tightened. Removing the top for access is not straightforward.

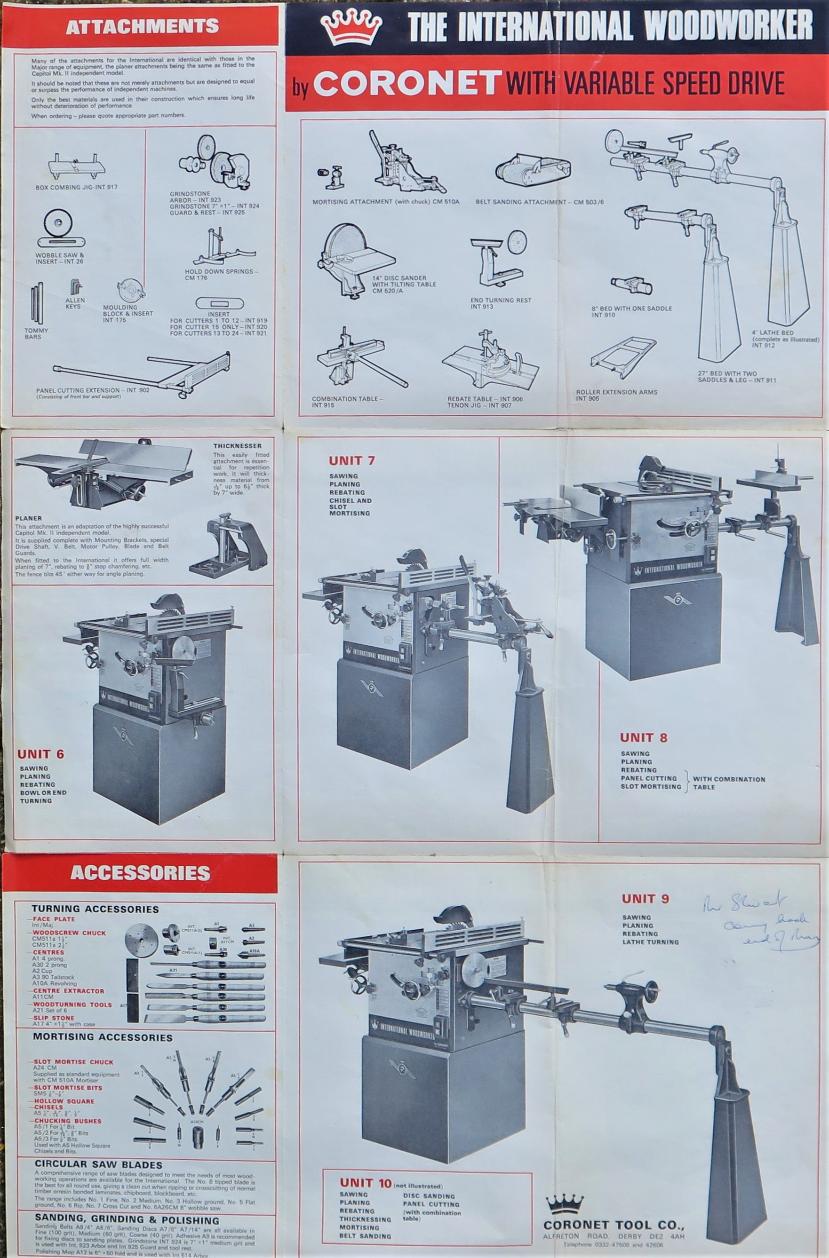

The saw spindle can be raised and angled. There is an extension support table that also holds the fence. A 4` long 2" dia lathe bed is supported at the tail end with a cast aluminium support. The lathe bed bar can be moved to a lower position for larger diameter turnings. A lot of the bolt on accessories designed for the Major will fit onto the International. I recently acquired a belt sanding attachment from Edmund Hills in Blackpool. I also have the slot mortice attachment and the planing and thicknessing devices along with the lathe turning equipment and tailstock. (M1 taper)

At

the moment it is set up with a sliding bed and used as a cross cut saw.

The

planer is set up to the left and is a fixed speed off the motor independent of

the variable speed control. At the moment the planer fence is set at 45 for

chamfering short lengths of timber. The machine is surprisingly quiet

running and a great pleasure to use, Eric stressed to me the importance of

keeping the bronze bush lubricated and this I have done religiously over

the years. The main steel bearing at the other end of the main shaft was

replaced a few years ago."

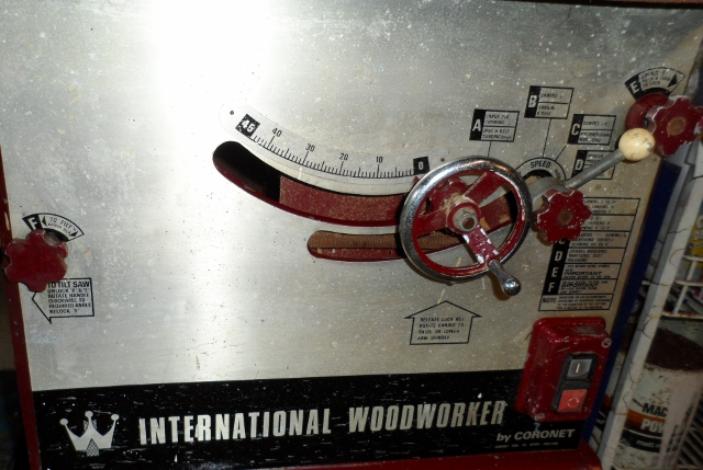

The picture below is the intimate teaser which Paul sent me in the first instance which hooked me immediately. All the words and pictures in the galleries are his own.

- FOR SALE

- About the Boleyn

- Home

- Zakwood Workshop Embu KENYA

- Julian Harrisons Workshop

- Inside the Boleyn (2005-2012)

- Inside the Boleyn 2013

- Inside the Boleyn 2014

- Inside the Boleyn 2015

- Inside the Boleyn 2016

- Inside the Boleyn 2017

- Inside the Boleyn 2018

- Inside the Boleyn 2019

- Inside the Boleyn 2020

- Inside the Boleyn 2021

- Inside the Boleyn 2022

- Inside the Boleyn 2023

- Inside the Boleyn 2024

- Inside the Boleyn 2025

- Technical Stuff

- Speed reduction gearbox fitting and operating instructions

- An Interview with Derek Pyatt

- Apollo no1 stove

- Coronet Imp bandsaw-blade-setting-advice

- Coronet Imp official hints on using

- Brook Gryphon 1hp motor connection diagram

- Charles Parker

- Coronet advertising etc

- Coronet Woodworking Machines catalogue

- Coronet Capitol planer

- Coronet Sovereign planer

- Coronet Classic 10 bandsaw

- Coronet Imp bandsaw

- Coronet Consort

- Coronet Elf

- Coronet Hobby lathe

- Coronet Home Cabinetmaker

- Coronet International Woodworker

- Coronet Major

- Coronet Majorette

- Coronet Major General

- Coronet Minor

- Coronet Minor paperwork

- Coronet Minorette

- Ernest's Coronet Minor

- Readers Machines

- More Readers Machines

- Even More Readers Machines

- Yet More Readers Machines

- MILFs

- Guestbook and comments

- Heimag A5 Tischbohrmachine